Global sourcing

We collect used cooking oils from around the world to use as raw materials for our biodiesel manufacturing operations.

Biodiesel manufacturing

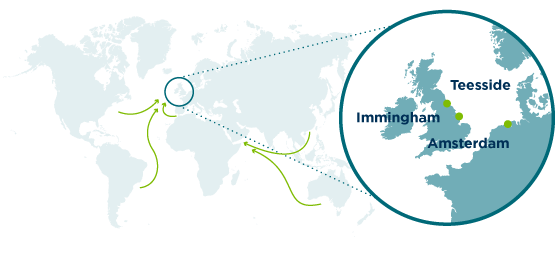

We own and operate two biodiesel manufacturing plants on the east coast of England and a third facility in Amsterdam that we acquired in 2018.

Biofuel blending and supply

By blending biodiesel made from waste oils, we minimise the land use change impacts and improve the carbon savings of the diesel we supply to customers.

We have developed unique supply chains that bring waste oils, collected from restaurants and other food producers around the world, to our manufacturing facilities in the UK and Amsterdam.

We have built long-term trading relationships with waste oil collectors globally, and have also invested in our own aggregation business based in Singapore and a joint venture collection business in Australia with Greenlife Oil.

With these diverse global supply relationships, we are able to:

By creating demand for waste fats and oils we are solving waste challenges and encouraging suppliers to dispose of their waste products responsibly.

In some instances, the used cooking oils we collect would have been poured down the drain which can create fatbergs, or even reprocessed illegally into animal or human food. By processing used cooking oil as a biodiesel raw material we mitigate this risk and assure our suppliers and municipal waste authorities that their waste has been disposed of safely.

We operate three biodiesel manufacturing plants: two in the UK, at Immingham and on Teesside, and a third in Amsterdam. Ongoing incremental investments have allowed us to expand production, create production efficiencies and process an even wider range of waste oils and fats.

Demand for waste-based biofuel is growing significantly, both in the UK where renewable fuel supply obligations are increasing year-on-year, and elsewhere in Europe.

We continue to invest in our manufacturing plants to improve efficiency and increase output. We have completed expansion works at our Amsterdam plant that will allow us to treat a wider range of feedstocks.

ESG Report 2022